CONCRETE HARDENER H35

PRODUCT DESCRIPTION

Concrete Hardener H35 is used in several industrial, construction and environmental applications. Its characteristics mean that it can be used as a fire retardant (increasing the critical temperature of the treated material), as a hardener, as a binder and accelerator of chemical reactions in concrete, but also as an insecticide, acaricide, fungicide or whitener.

Concrete Hardener H35 is a water-based, odourless and non-toxic product. When penetrating the substrate, it reacts chemically to generate an extremely solid structure in the capillaries, making the substrate and its alkaline environment stable over time and resistant to the migration of chloride ions, carbonation, the aggression of run-off acid water.

Concrete improves considerably, both in appearance and technical features, through surface treatment with Concrete Hardener H35. This penetrates into the porosity of the substrate, chemically reacts with Ca(OH)2, produced by the hydration of the cement to form calcium silicate hydrate.

The impregnation of the pores, besides improving aesthetics, drastically reduces the permeability to water, but not to vapour, increasing the surface hardness, the durability of the concrete and in particular the resistance to acid aggression. By allowing humidity to escape, risks due to the freeze-thaw cycle are avoided.

Concrete Hardener H35 penetrates into the porosity of the cement and, the very first application completely invades all the porosity, even capillary, reacting with Ca++ ions as mentioned above. The formed gel slowly contracts by 20% leaving the pores filled with 80% of the initial volume. After the second application, the pores remain empty for 20×0.2 = 4% and full for 96%. After the third application, the pores remain empty for 20%×4 = 0.8% empty and full for 99.2%, i.e. practically full and therefore inaccessible to liquids. The silicate anions contained in Concrete Hardener H35 react with the calcium ions present in the hardened cement, forming a silicate calcium gel resistant to water and other liquids, depending on the reaction: Ca++ + SinO2n+1 -> CaO ∙ SinO2n+1. This reaction occurs inside the pores of the cement. The Ca-silicate gel clogs the porosities, making the cement waterproof to liquids and at the same time harder, more resistant to wear, insensitive to carbonation and more resistant to the aggressive action of acids.

PRODUCT DESCRIPTION

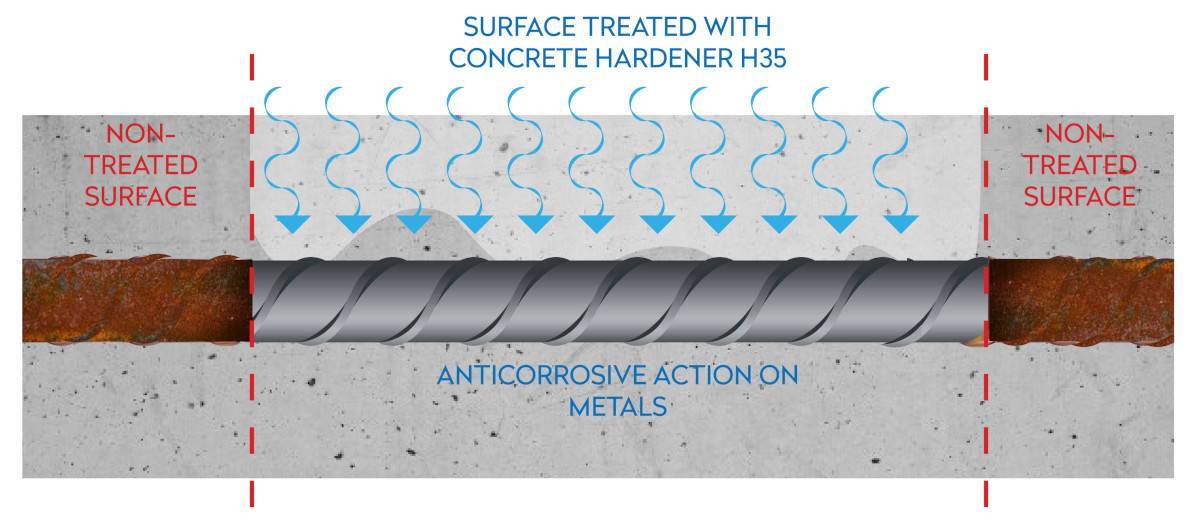

Concrete Hardener H35 exerts an anti-corrosive action on metals that it comes into contact with, such as concrete reinforcement.

The Concrete Hardener H35 in contact with metals forms monomolecular films of metallic silicates, impervious to oxygen and acids and therefore acts as anticorrosive. The Concrete Hardener H35 is able to penetrate into the capillaries of the concrete thanks to its low viscosity and especially low surface tension that sets it apart from other products that you can find on the market. Thanks to its features, Concrete Hardener H35 penetrates deeper and allows you to achieve excellent waterproofing.

CONCRETE HARDENER H35

FIELDS OF APPLICATION

IMPREGNATION INCORPORATED TREATMENT

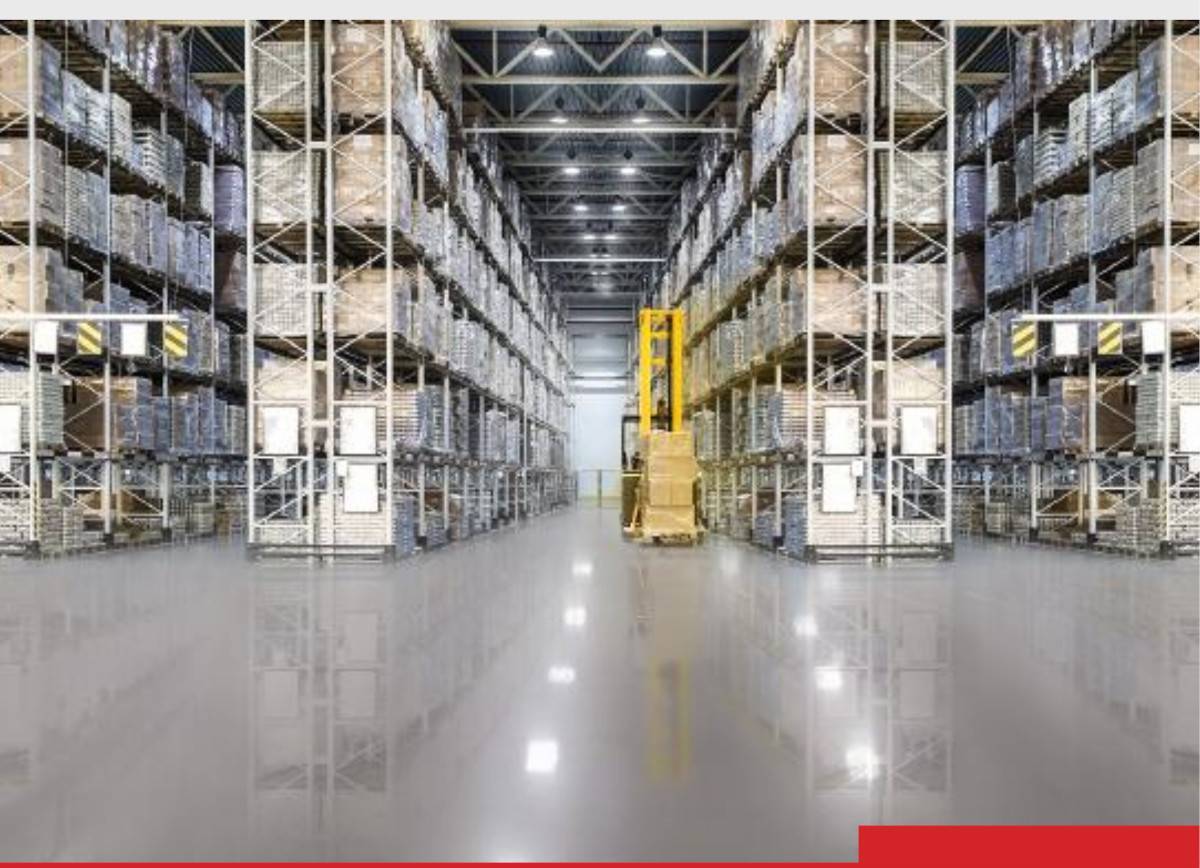

For indoor, outdoor, new or existing Concrete or Cement floors that need to implement resistance to abrasion and hardness, impermeability to liquids, without altering their breathability, offering a stable aesthetic degree. Intended for residential, commercial and production areas such as:

-

Densifier for new floors.

-

Densifier for existing floors

-

Architectural concrete floors, shops, showrooms, production, packaging and warehouse areas.

-

Garages and parking areas.

-

Cement plasters.

-

Prefabricated panels or exposed concrete blocks.

-

Sealing and anti-dust treatments.

-

Treatment in the smoothing of concrete floors.

USE

The floors treated with Concrete Hardener H35 acquire: hardness, scratch resistance, greater friction coefficient, resistance to chemical agents due to reduced liquid absorption.

-

Resistance to freeze-thaw cycles, sulphates and chlorides.

-

Reduces the absorption of liquid water (better waterproofness) without altering the passage of water vapour.

-

Increased resistance to chemical aggression, stains and dirt.

-

Protects the surface from tyre tracks or rubber threaded wheel tracks such as forklift trucks.

-

Prevents efflorescence, mould and fungi due to rising damp.

-

COV, almost null.

-

Protects against contamination by mineral and vegetable oils.

-

By acting on the internal cohesion of the concrete, it increases the compression and abrasion strength.

-

In the case of cement colour treatment with Concrete Colour Dye, it protects the applied colour by slightly intensifying the shade and gloss.

-

Area put back into service a few hours after the treatment.

-

Applying Concrete Hardener H35 makes the flooring safe, increasing the surface friction coefficient.

To make the floor resistant, non-slip, hard and aesthetically pleasing

CONCRETE HARDENER H35

FIELDS OF APPLICATION

CURING COMPOUND

On freshly laid concrete works, it prevents rapid evaporation of water.

ADVANTAGES

-

Increases the mechanical resistance of the concrete.

-

Reduces shrinkage and drying cracking.

-

Limits the absorption of the substrate by reducing stains and chemical aggressions.

-

Solvent free.

-

Colourless and odourless.

-

Concentrated product.

USE

ON HARDENED/MATURED CONCRETE

For impregnating anti-dust treatments, it is recommended to wait for the concrete to cure in order to allow greater penetration by absorption.

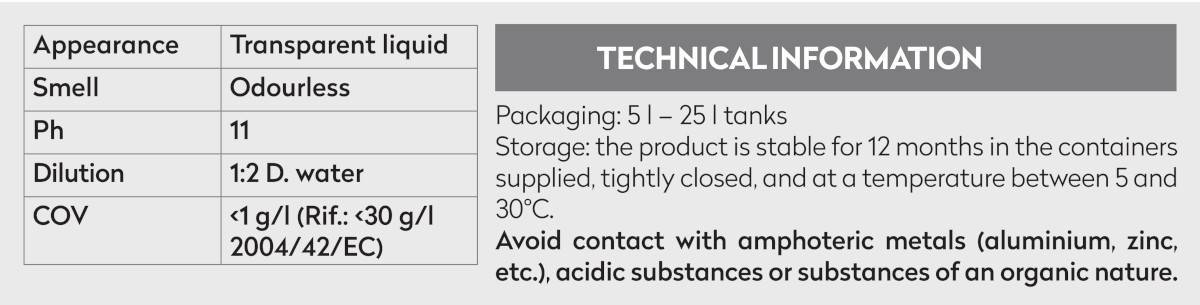

Dilute CONCRETE HARDENER H35 with Demineralised Water or Distilled Water in the respective ratio 1:2. (In case of poorly absorbent substrates, a greater dilution is possible up to the ratio of 1:3 ).

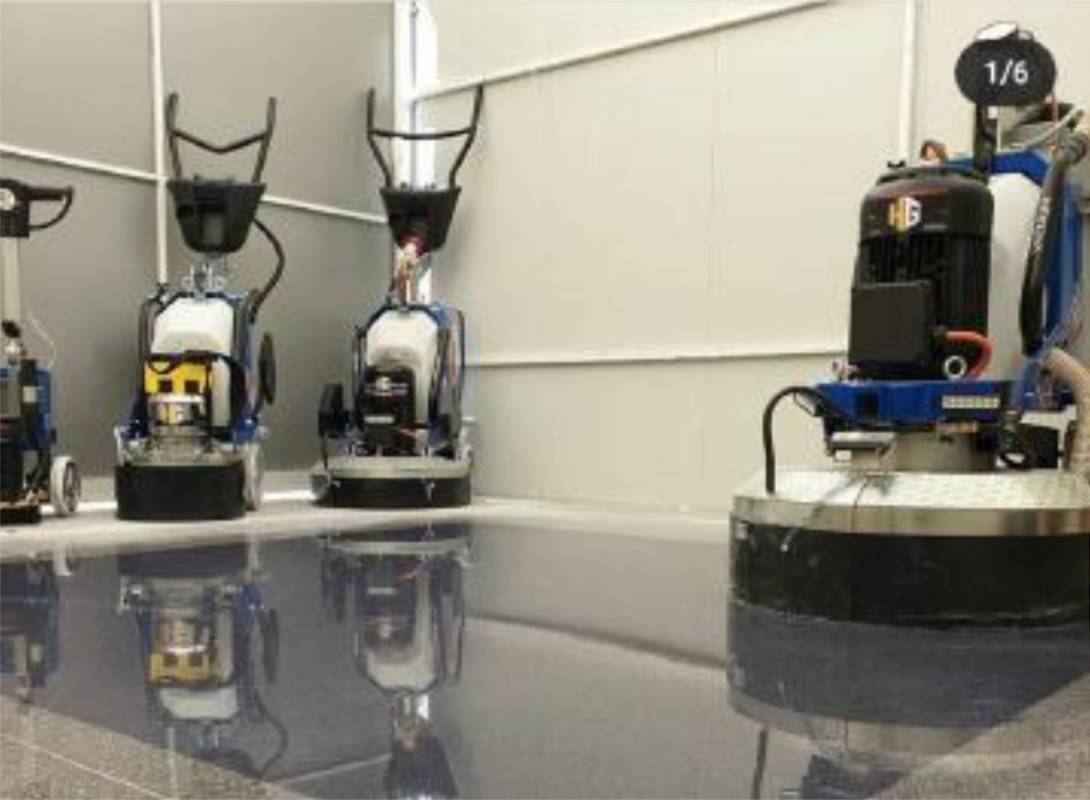

On a clean and dry surface free of cement laitance, spray Concrete Hardener H35 using a low pressure pump and distribute it evenly with brushes or mechanical means (e.g. single disc machines), keeping the surface moist with product, until a slippery gel forms (after approximately 30 minutes).

If liquid absorption is slow, spray water on the surface, continuing imbibition until the excess or shiny areas disappear and in any case rinsing the slippery residue. Repeat the application for the second and third time.

In the case of existing floors resting on the ground, make sure there are no damp areas or negative pressure.

Attention: surfaces that have been cleaned or treated with acidic substances should be neutralised before the intervention.

Use industrial mops on surfaces with a rough profile such as brushed concrete.

To make the floor resistant, non-slip, hard and aesthetically pleasing

CONCRETE HARDENER H35

USE

ON FRESH CONCRETE AS CURING COMPOUND

It must be carried out on freshly cast concrete, after trowelling or smoothing, always recommending a preliminary test in order to verify the absence of interference.

>> Only intervene on the concrete surface when there is no surface water and when the mechanical performance of walkability and workability is achieved.

Dilute Concrete Hardener H35 with Demineralised Water or Distilled Water in the respective ratio 1:2. (In case of poorly absorbent substrates, a greater dilution is possible up to the ratio of 1:3 ).

Spray Concrete Hardener H35 using a low pressure pump and distribute it evenly with brushes or mechanical means (e.g. single disc machines), keeping the surface moist with product, until a slippery gel forms (after approximately 30 minutes).

If liquid absorption is slow, spray water on the surface, continuing imbibition until the excess or shiny areas disappear and in any case rinsing the slippery residue.

Repeat the application for the second and third time.

The Concrete Hardener H35 mixed directly into the concrete spraying nozzle (spritz beton or sprayed concrete techniques), facilitates the immediate setting of the cement allowing the application of several layers of concrete of considerable thickness.

WARNINGS

-

A suitable mechanical preparation is essential before applying surface finishes.

-

Low temperatures increase the gelation time.

-

High temperatures reduce the gelation time. In these cases, make sure to keep the surface moist for at least 30 minutes.

Do not use sprayers previously used for release agents or silicone products.

3 days after the first application, the surface can be wetted with water to check its absorption, bearing in mind that the complete development of the features takes place gradually and on average in 15 – 30 days.

In very old cements, the calcium present is almost all insoluble and therefore not capable of generating Ca++. In this case, a preliminary treatment with a 5% solution of calcium nitrate or calcium acetate is required.

YIELD

The yield of Concrete Hardener H35 depends on the roughness and absorbing power of the substrate as well as on the laying method.

In sanding cycles, on cured substrates, consider 30-45m2/L (AS CONCENTRATED PRODUCT TO BE DILUTED).

As Curing Compound, consider 12-20 m2/L (AS CONCENTRATED PRODUCT TO BE DILUTED).

CONCRETE

HARDENER

H35